There are many potential ignition sources in a refinery or a petrochemical plant, including hot work, stationary, mobile and vehicular internal combustion engines, as well as improperly maintained lighting or electrical equipment. |

These are typically controlled via measures such as traffic control, hot work permits for welding and burning, vehicle entry permit requirements to operate diesel engines in the posted areas, proper maintenance of electrical equipment and programs to prevent and detect the release of flammable materials. These measures are a good first step; however, due to human involvement at each step, complex processes do not ensure a safe environment. In the case of hydrocarbon release, a running diesel engine will be the first one to consume large amounts of hydrocarbon vapors, quickly enter runway condition and become a dangerous ignition source.

|

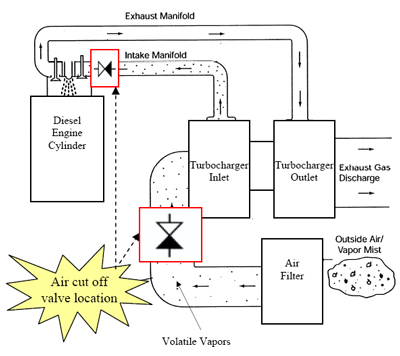

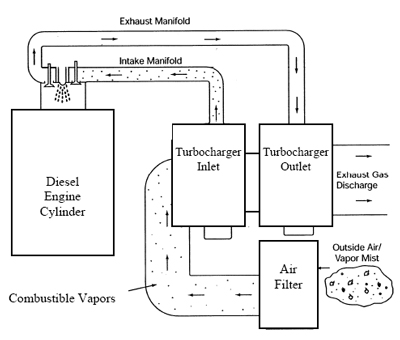

Diesel engine runaway is a serious problem in plants and facilities where hydrocarbon emissions or leaks may occur. A runaway can be described as an engine running out of control on an external fuel source, and the operator cannot shut down the engine using conventional methods. Turning off the engine ignition switch, fuel system, shutting off the solenoid or disengaging the engine's load will not stop a diesel engine. The most effective way of shutting it down is with a diesel engine air cut off valve. |

Diesel engine speed is governed by the controlled amount of fuel fed to the engine through its normal fuel system and by its internal speed governor. When additional uncontrolled fuel is present in the environment in the form of combustible vapors, the engine may ingest them. This adds additional uncontrolled fuel intake, which causes the engine to over speed. Turning off the normal shutdown system will only turn off the engine's normal fuel source, permitting the engine to run uncontrolled by the external fuel source. |

In a total runaway engine situation, the result can range from minor engine damage to engine explosion, causing catastrophic damage to the equipment and surrounding facilities and/or death or injuries to personnel.

Figure 1. Typical air intake system with a four cycle diesel engine |

The Problem |

According to OSHA, there have been 36 incidents related to the release of highly hazardous chemicals in the refining industry since 1992, causing 52 deaths and 250 injuries. U.S. Minerals and Management Service, the U.S. government agency that regulates the offshore oil industry, has determined that alarmingly high percentages of fires and explosions result in death and destruction. More than 20 people have been killed and 190 injured in just three accidents. |

In 1985, the U.S. Department of Labor, Mine Safety and Health Administration established and enforced regulation 30 CFR 7.98, Technical Specifications. Per this regulation, diesel engine air intakes shall be equipped with a device to shut down the diesel engine in the event of runaway. NFPA (1999) permits installation of a manual emergency shutdown device on the intake or exhaust system to prevent engine over speed. The U.S. Coast Guard requires air intake shutoff devices in certain applications. |

Since 1971, Canadian (Alberta Regulation 151/71 Oil and Gas Conservation Regulations 8.100) and European regulators (regulation EN 1834) have similar regulations that require all vehicular and stationary diesel engines working in a hazardous area to have an air intake shutoff valve to prevent the engine runaway condition. ISO 3046-6:1990 standard, Reciprocating Internal Combustion Engine, also requires an over speed protection device to prevent engine runaway. |

Some engine manufacturers offer an emergency air intake shutoff valve as standard equipment. To reduce diesel engine runway risk, mining, oil and gas, refining and petrochemical companies must specify air-intake shutoff valves for new engines and retrofit their existing engines operating in and around the hazardous areas. Air intake shutoff valve manufacturers offer a complete installation kit for different engines to make it easier to install the valve in the field. |

California has a regulation (subchapter 14, Petroleum Safety Orders, Drilling and Production Article 35, Drilling and Well-Servicing Machinery and Equipment) that specifies, "For a diesel engine, a quick closing valve or equivalent device that will shut off the air into the engine's air intake manifold, a means of releasing the engine compression, provided it is done in a manner that will not produce an open flame or spark or other safe means will be acceptable." |

Cal-OSHA has recently approved a petition that will expand the current standard to include stationary vehicular and mobile equipment using diesel engines operating in hazardous areas. Details of the new standard will be finalized in an upcoming advisory committee meeting. |

Some foreign oil and gas companies from the Middle East, Africa and Asia are requiring stationary and vehicular diesel engines to be fitted with air intake shutoff valves to prevent engine runaway condition. |

By eliminating sources of ignition in mobile vehicles, refineries and petrochemical plants can improve safety and reduce risk associated with operating equipment in hazardous environments. This safety policy should apply to all diesel engine equipped machinery including pickup trucks, fork lifts, cargo tank motor vehicles (CTMV), aerial lifts, welder's trucks, etc.

This safety policy should apply to common ignition sources in the oil and gas, chemical, petrochemical, mining and transportation industries (see Table One). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table One. Common Ignition Sources

The Solution |

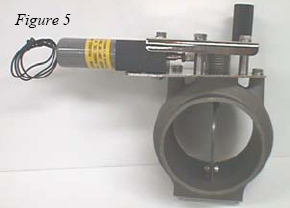

Diesel engines come in a variety of design configurations and fuel schemes, but handle air the same way for combustion. Providing an effective combustion air control is the key to prevent diesel engine runaway. Several manufacturers offer swing gate, guillotine and butterfly design air intake shutoff valves with local, remote control and automatic shutdown capability. Customers prefer swing gate and butterfly design, as seen in Figure 3, due to their light weight and compact design that makes them suitable to install in a tight engine compartment. These valves are typically made from corrosion resistant aluminum. Guillotine type valves use a spring-loaded knife gate that makes them more difficult to install on compact engines, due to their overall weight and size. |

Diesel engine air cut off valves are available in many sizes to accommodate different air intake piping. Installation may require special hardware that includes clamps, hump hose reducers and special adapter elbows used when there are size differences between the valve and piping. |

Valves are typically installed as close as possible to the engine air intake manifold. High temperature valves that can withstand 450 deg F are available if higher than normal engine temperatures are present. It is essential to have solid metal connections between the valve and engine. If the valve cannot be mounted directly to the intake manifold (because of size and space restrictions), all rubber hoses and elbows between the valve and the intake manifold must be replaced to prevent the possibility of valve movement toward the engine during a shutdown.

|

|