Oil quality assessment causes lubrication issues at a refinery.

On Friday, January 7, 2011, a processing unit was shut down due to a sequence of events that led to the loss of main fractionation tower bottoms circulation at a refinery. The east bottoms circulation train, which consisted of a turbine, gearbox and pump, was already out of service for a pump bearing repair. The west bottoms circulation train had been in service for several days prior to the event.

Lubrication Issues

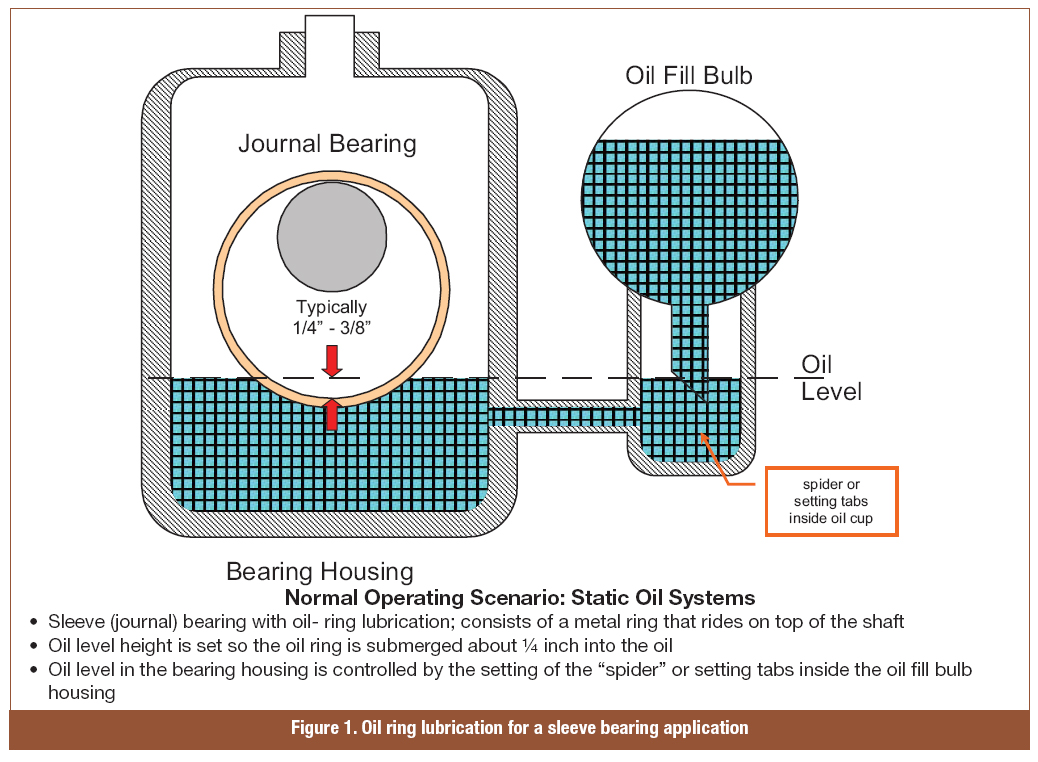

The day of the event, the lubricating oil in the west turbine was reported to be dark and the bearing housing temperature was externally measured to be approximately 350 degrees F. The unit was safely shutdown and the equipment prepared for maintenance. The pump and turbine are equipped with oil rings that provide lubrication to the bearings. See Figure 1 for a cut-a-way of the oil ring design for turbine.

The Basic Operator Training course for the refinery instructs new operators to check the lubricating oil for moisture, particles and breakdown by draining a sample from the bearing bracket so that the condition can be visually assessed. This technique, however, does not take into consideration the size of the bearing bracket reservoir or the design of the bearing.

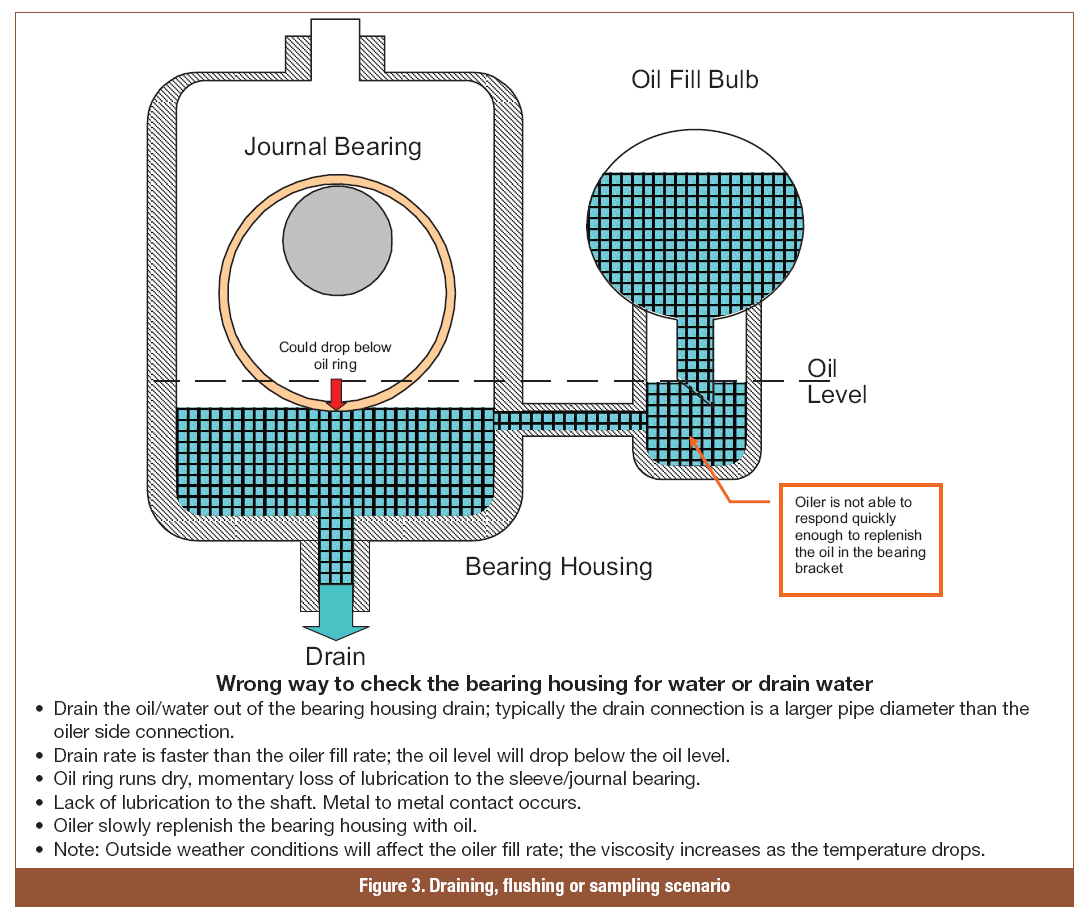

In this particular situation, the turbine is equipped with a journal bearing with only a small lubricating oil reservoir. As a sample of oil is removed from the bearing housing, the oil level in the reservoir drops below the oil ring (See Figure 2).

The lubrication to the journal bearing is, therefore, temporarily interrupted. The oil level in the bearing housing subsequently drops below the oil level setting in the side oiler and the oiler starts to replenish the oil in the reservoir, but the fill rate can be slow depending on outside temperature conditions. The bearings had failed because the oil replenishment took too long after the samples were taken. The bearing ran without adequate lubrication. The oil film was depleted and the shaft rubbed the babbet bearing.

Confirmation of the Failure's Cause

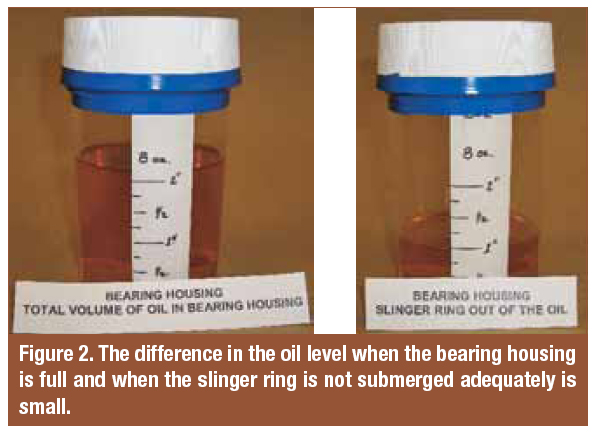

To confirm the cause of the failure, a test was performed in a controlled shop environment (the shop temperature was approximately 68 degrees F) with the same type of turbine, bearing bracket and lubricating oil. Proper oil level was established in the bearing bracket and then all the oil was drained to get a measure of the total volume (See Figure 3).

The oil removed was replenished to the bearing bracket, and a second sample was pulled. The second sample removed only enough oil from the bearing bracket to drop the oil level below the oil ring as illustrated in Figure 3. This amount of oil in the sample jar was determined to be very close to the total amount of oil in the bearing bracket.

Also during this test, the replenish rate from the side oiler was timed to see how long reestablishing the reservoir to the proper level for satisfactory oil ring operation would take. It took seven minutes for ISO grade oil at 68 degrees F to replenish the level in the bearing bracket through the ¼-inch NPT connection for the side oiler. Note that the fill rate will be slower for the colder outside temperatures experienced with the application. The investigation followed a Latent Cause Analysis methodology to determine the root cause of the event—as samples are taken to test the oil, the reservoir was not replenishing the oil quickly enough.

Conclusions

Because the west pump was out of service for repair, the east pump/turbine was critical to the unit's availability. To ensure reliable service, the unit operators increased the monitoring rounds on the main fractionation bottoms circulation train. The lubricating oil was sampled frequently from the pump and turbine to check for moisture, particles and oil breakdown (darkening).

The New Operator Training program only briefly covers the generic steps to check for moisture or breakdown in equipment with wet sump lubrication, and it did not provide adequate steps to prevent this type of failure. The program should be expanded to cover the generic oil check steps and expanded to include specific designs so the unit operators can provide proper monitoring techniques. The expanded program will provide new operators with the foundation to expand with experience to prevent this type of failure from reoccurring.

Pumps & Systems, October 2011